Appreciation of Fine Castings(four)

2024-03-21 08:00

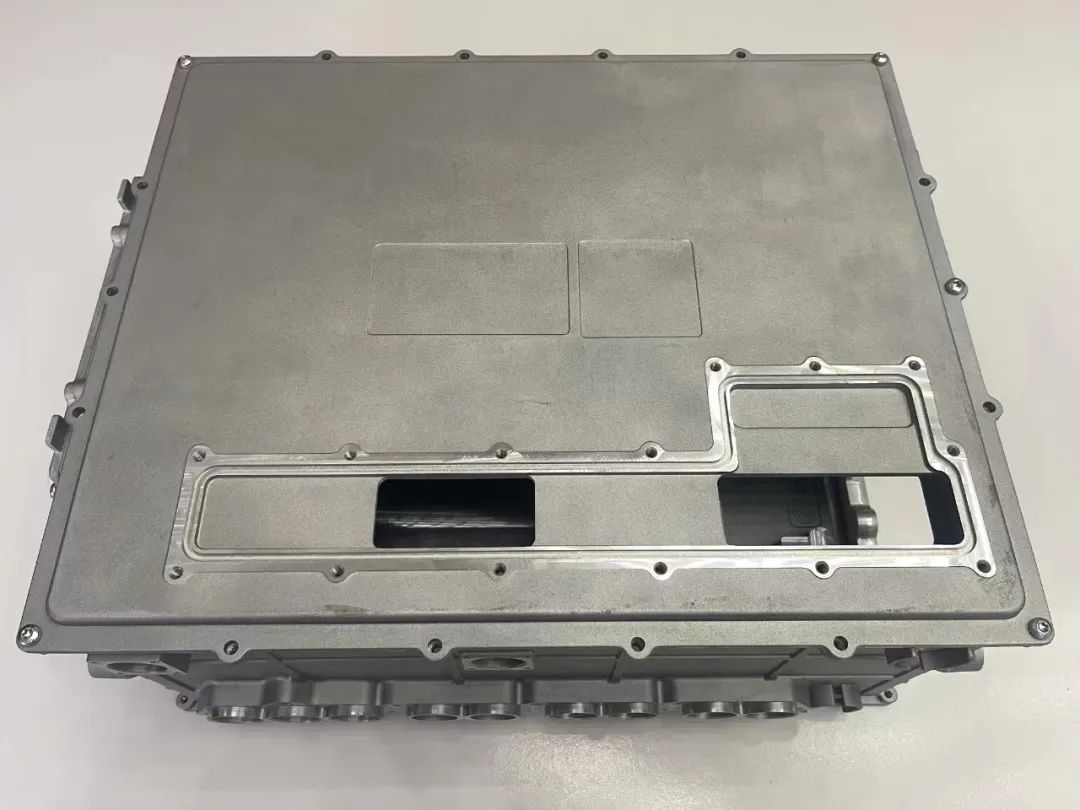

Name of Die Casting:

Electric Control Box Housing

The successful development of the die casting mold for the entire set of the electric control box housing for new energy electric vehicles is the integration and application of a multitude of technical systems such as materials, heat treatment, mold design, die casting processes, machining, assembly processes, management, quality control, and more. It constitutes a vast system engineering project. Among these, the design of the die casting process plan is an extremely important aspect, as the reasonableness of the process directly affects the quality of the casting and the subsequent production processing stages. The electric control box housing has a complex structure with high internal quality requirements, such as threading that must not have any faults and a porosity rate that must be ≤2%, etc. For such complex-type die castings, a good die casting process design plan plays a decisive role in the quality of the product.

To address these challenges, the company has adopted a gating system design and vacuum extraction solution. The die casting mold operates under high temperature and high pressure, demanding materials that have high thermal fatigue resistance and are also structurally complicated, with significant variations in wall thickness. Moreover, they are required to pass a leakage test under high pressure. Therefore, defects that can cause leakage during casting, such as shrink porosity and die sticking, are the first to need to be avoided. A gating system that meets the requirements of the die casting process was selected, especially in terms of the position and guidance of the internal gates, which should facilitate a steady and smooth flow of molten metal, systematically expelling gases from the mold cavity to achieve an effective filling and prevent die casting defects. An analysis of the structure and performance requirements of the product was performed for gating system design. First, casting simulation software was used to conduct a numerical simulation analysis of the pouring and overflow system including filling, particle tracking, air pressure, temperature, solidification, and other processes. Then, based on the analysis results, the reasonableness of the plan design was confirmed, and finally, the validation of the process design plan's reasonableness was conducted through production trials.

Get the latest price? We will reply as soon as possible (within 12 hours)